Description

Rising rate replacement performance lowering springs for Camaro Gen 6. Direct fit replacement. Works with Magnetic ride control shock absorbers. For V8 models only; lowers the car 1-1 (slightly less for ZL1 models). Provides superior ride quality for over the road enjoyment, while rising in rate to handle track and autocross with ease. Designed by John Powell, engineered by Hyperco, made in the USA.

Lifetime warranty for loss of rate or breakage.

Works best with ZL1 front and rear sway bars and Powergrid end links (available separately).

Ride Height

As with all Powell Suspension set ups, these are designed for racing rather than simply lowering your car for looks. If you would like more height adjustment and variable suspension settings, check out our ZZP Camaro Coilovers.

- 4 Cylinder Models ~ approximately factory ride height front and rear. But, these are not designed for 4 cylinder models due to the reduced weight on the front. We recommend our coilovers instead.

- V6 Models: Have not tested yet for height.

- V8 Models ~1/4" drop front and rear.

More Info

Some words from John Powell -creator, Marc Campbell and Evan McClure– Hyperco Engineers

We assumed the car would be most often driven with a maximum of two people, weighing around 200-140 lbs each; full tank of gas; basic safety kit and tools in trunk. The car would be used for daily driving and potential track use, and not used for towing or extreme load situations. Tires would be street specific performance tires, or “R” compound tires, perhaps occasionally racing slicks for limited track use.

We measured multiple cars to determine build quality and suspension parameters. We studied the range of travel of the suspension components; and decided to produce a spring that would run trouble free with Magnetic Ride control. Additionally, our springs would fit properly on OEM struts and shocks including MRC, but also fit our own tuned damping struts and shocks, which we plan to, offer in the near future. Finally, we tested the latest GM Multimatic Chevy performance suspension components.

Our drop with Gen 6 YYZ v2 springs is one inch from 1LE SS stock.

It took a lot of time and effort to accumulate the parts and run the analysis. We also had to review the information from our stalwart Gen 6 independent testers, Michael, Nick and Sean. You could say they were not “independent” as I gave them the springs at no charge to test. But trust me, if I sent these folks junk , they would be all over me in a New York minute.

They did tell me what changes we needed to make (fitment, coil ends, YYZ script right side up etc) but here is the graphical information on all the springs we reviewed, including the $6,000 dollar Chevrolet Performance package. That did include some suspension pieces and trick Multimatic shocks.

I figured that with computer simulation, and really bright kids out of school as engineers, the springs on the market would be decent.

And yet, I was disappointed. Some of these springs are weak and will continue to take set as you drive them, which by the way will cause the wheel alignment to change and the tires to wear adversely. The spring rates on the Chevy package, as you can see from the graphs are really high. The days of doing the “Porsche/BMW European style” of redonkulous high spring rates for race cars are long gone. Tracks and roads in North America are not billiard table smooth surfaces. Race cars need wheel travel and wheel rates and damping to suit, to make tires work well, generating grip, factoring in tire compound, track surface, changing track conditions and aero load. And for the Gen 6 by the way, you may well be driving the car to the track days.

For sure the more grip the tire has, especially a racing slick, the demands on the spring rate and the suspension are greater. But if you choose the Chevy performance linear spring package, I suspect you had better wear a kidney belt for the drive..../end rant Wow !! Look at these graphs

Evan McClure, the Hyperco engineer on our project, has been sweating the details with our test stuff and my insistence that we want the very best rising rate springs for Gen6 Camaro customers .

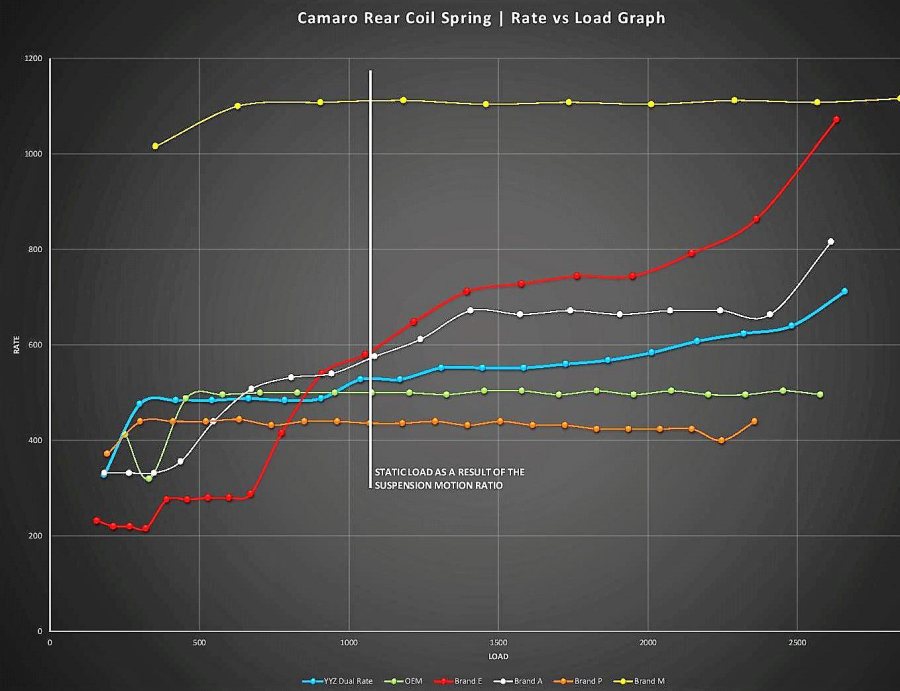

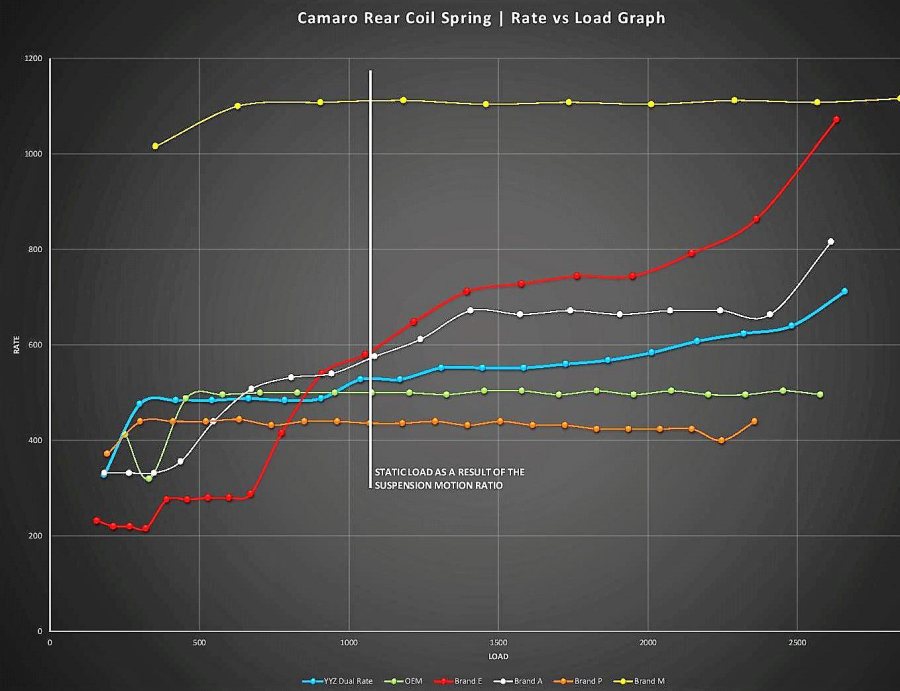

Evan says: “What you’re looking at, are rate vs load graphs. This shows the relationship between the load (lbf) each individual brand’s spring Sees and the corresponding rate (lb/in) it’s at during that load. The higher the graph line, the higher the rate. The higher the rate, the stiffer the ride becomes. What these graphs show, on both the front and rear, is that the Hyperco-Powell Racing YYZ Springs are the ONLY springs tested on the market that takes the static load of the Camaro’s alpha platform into account for rate transition. Every other brand is either focused on looks only (lowering spring with a linear rate), or creating a ride that “simulates” a sporty ride (harsh on bumps, minimal body roll). The YYZ springs are the ONLY springs that have a true dual rate setup, and are focused on both form and function. By utilizing the static load as a result of the motion ratio as our transition point for our dual rate system, we’ve created a ride that is soft around town, but stiffens up around corners. A dual rate system creates a reduction in body roll, and will create what I believe to be optimum cornering grip around the track and launch grip at the drag strip. “

The choice is yours. When it comes to performance lowering springs, we believe Hyperco Powell YYZ springs are the best you can buy. Shock damping is next up.

Stay tuned.

YYZ V.2 Gen 6 Camaro FRONT spring comparison graph.

Here is a graph representing the front springs we measured. Mark Campbell, our Engineering Guru at Hyperco, explains it like this.

“The place in the graph where the spring is compressed at ride height is marked with a line as “static load etc”

Notice the front YYZ springs are rising rate springs, and all the other springs are linear in rate. With an initial linear rate section, the YYZ are close to the OEM spring at trim height, but then ramp up in rate as further deflection occurs such as during hard cornering. Springs “E” and “P” have lower rates at load than YYZ. Spring A has initially slightly more rate than YYZ, but like all the competitors, is a linear spring.

What this means to the driver: YYZ will yield a good ride, and exceptional turn in response on the track. As the load increases through the corner, the YYZ springs continue to handle the increased weight transfer to the loaded front spring while supplementing the anti-roll bar with additional roll stiffness from the increasing rate. On the street, the car will ride smoothly, but when subject to rough roads, frost heaves or potholes, the spring can absorb the impacts without reaching solid load.

Spring P, in particular, will just bottom out (reach solid load) when the car hits a pothole, for example. And Spring P on the track will also be less than stellar during hard cornering because it does not have enough rate for the increasing load. Spring E doesn’t do much better on the track, and as detailed, none match YYZ for rising rate capability.”

YYZ V.2 Gen 6 Camaro REAR spring comparison graph.

The rear spring design on the Gen 6 was interesting to me and a challenge for the Hyperco engineers. The front was relatively simple in execution, there is good wheel travel. At the rear, wheel travel is not as great a range as I would like, and the limit of travel is not the compression of the spring or a spring bump stop, but the rear shock itself.

The other thing that factored into the Gen 6 YYZ rear spring design was something I learned from racing Gen 3 and Gen 4 Camaro. Most racers want stiff springs, but to put the power down, to really hook up and get good traction, weight transfer and spring compliance is needed. Throwing ever stiffer spring rates at the rear will support the car if there is a lot of added aero downforce, and protect the shock, but it surely will not help traction. Traction off the drag strip line, or off the road race corner is really important. For the street, good traction in adverse weather conditions is an advantage. The Gen 6 has some really stout torque numbers, so we knew what we needed.

How did we do? Mark Campell says:

“Let’s look at the graph. OEM is the bench mark. Spring “P” has way less rate and is linear. OEM is linear. Spring E and A are way above the OEM benchmark. What is important is that YYZ starts at about the OEM rate, and then gently ramps up progressively through travel. The spring “M” is way off the charts for rate stiffness; Spring E and A rise in rate but are also quite stiff. So stiff that traction is adversely affected. That’s what Tester Nick found out on track, and YYZ gave him really good forward traction off the corner. Coupled with the favorable front spring rising rate, YYZ performed very well for Nick, in cold weather at the last track day of the year, without optimizing the alignment at all, due to circumstances at that time.

Tester Sean struggled with some of the springs he had tried, spring B he had to return as the springs were mismatched in free length, and translated to uneven static ride height side to side.

Once YYZ were installed, Sean noticed immediately the really good “hook” on launch. He also liked the ride. Look at the graph and you can see why YYZ are able to show improvement.”

About Hyperco

Hyperco is a supplier of precision engineered, high-performance suspension springs and related components supporting the Motorsports, Street Performance and Off-Road/Powersports markets. In 1996, Hyperco joined MW Industries Inc. to become one of the top spring and specialty fastener manufacturers in the nation. Today, Hyperco products are engineered and manufactured at our sister locations of Matthew Warren Spring in Logansport, IN and Pontotoc Spring in Pontotoc, MS. MW Industries, Inc., headquartered in Rosemont, Illinois, is a leading manufacturer of highly engineered springs, specialty fasteners, machined parts and other precision components to more than 45,000 customers in over 35 countries. Its 100,000+ products are sold through a combination of direct sales, catalogs and distributors to original equipment manufacturers and aftermarket customers in a number of industries, including aerospace, medical, electronics, energy and oil, agriculture, construction, transit, heavy trucks, automotive, motorsports, performance aftermarket, industrial, consumer products and military.

These are drop shipped from Powell Race Parts.