ZZP offers these aftermarket cams for your LSJ engine. When paired with better valve springs, the lobe, duration, and lifts are modified to improve your midrange and high RPM power and torque. We also offer supercharged and turbocharged specific profiles to better suit your power adder. When you replace your cams, you will NEED to replace your valve springs and retainers, we recommend our 82# valve springs and retainers. It is not required, but highly recommended to remove or replace your balance shafts with our neutral balance shafts or balance shaft delete kit. The stock camshaft bolts are torque to yield and should be replaced when installing cams, we have upgraded non-TTY bolts found here.

Supercharged:

The Stage 1 cams are recommended for most supercharged builds, these cams will raise your powerband about 500rpm.

The Stage 2 cams are the next step, they will raise your powerband about 700-1000rpm, they will make peak power around 7500-7800rpm! They will require an ATI balancer to help reduce engine vibrations at the new high RPMs.

The Stage 3 cams are recommended for all out race cars, not intended for street cars due to their high rpm powerband.

They were designed for our all out drag car with the 2.4L stroker engine. These are the cams that Turbo Tim ran in his 401whp, stock m62 blower, stroked 2.4 liter Saturn Redline that makes peak power at 8500rpm.

ZZP S2 is 216/218 @ 1mm and 10.78mm/10.69mm lift, 111 LSA

ZZP S3 is 216/224 @ 1mm and 10.78mm/11.10mm lift, 113 LSA

Turbo cams:

"Stage 2 turbo" cams are 212/212 duration at .050" with .419 lift. The centerlines are 109 intake/115 exhaust. Duration @ .006" is 256/256. We have had good results with these cams for fairly modded street cars.

"Stage 3 turbo Reverse Split" are 218/210 duration at .050" with .437/424" lift. These cams are intended for race setups with a large exhaust wheel and very free flowing exhausts.

Our cams have been cut with the correct keyway location so you will not need to install adjustable cam gears to get the cam timing set correctly. If you buy Ecotec cams directly from COMP Cams they WILL NOT come correct. This is why we dropped our COMP Cam cam line, they were never timed correctly for the LSJ engine.

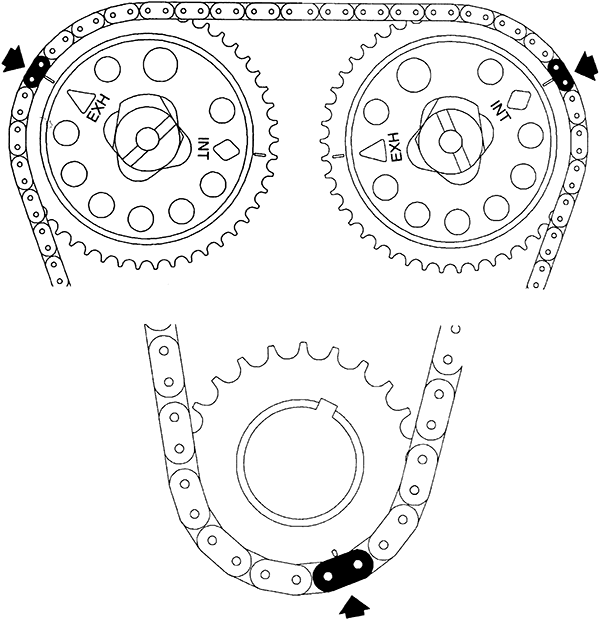

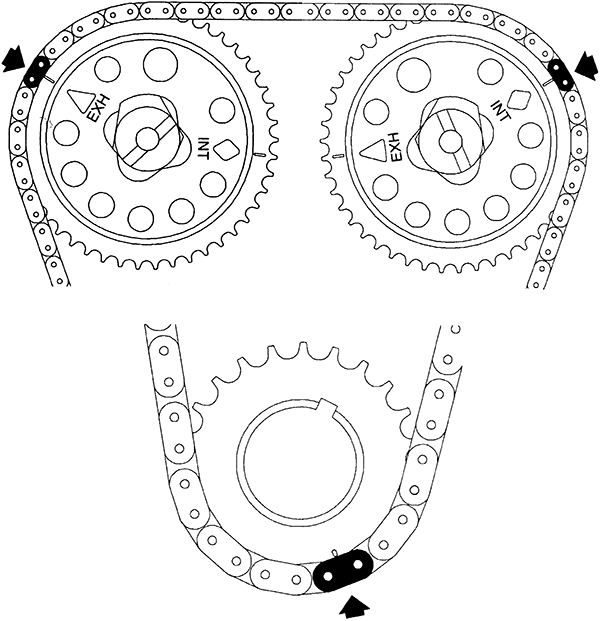

When timing Ecotec cams:

Cylinder 1 and 4 should both be at TDC when the notch in the hex lines up with the line on the sensor housing. However, you need to make sure cylinder 1 has just completed the exhaust stroke and cylinder 4 has just completed the compression stroke. At that point, cylinder 1 exhaust valves have just closed and cylinder 1 intake valves are starting to open. If #4 exhaust valves have just closed, then you need to aim the notch 180 degrees off from the line in the housing.

Installation Procedure

GM Performance also had cams available, but we found that they did not work well on LSJ applications. They were developed several years ago for 2.2 motors.*

In this situation, the lash really only refers to taking up lift that would otherwise be caused by the diameter of the base circle. The cam duration measurements assume zero lash and 1mm lift created by the lobe only.