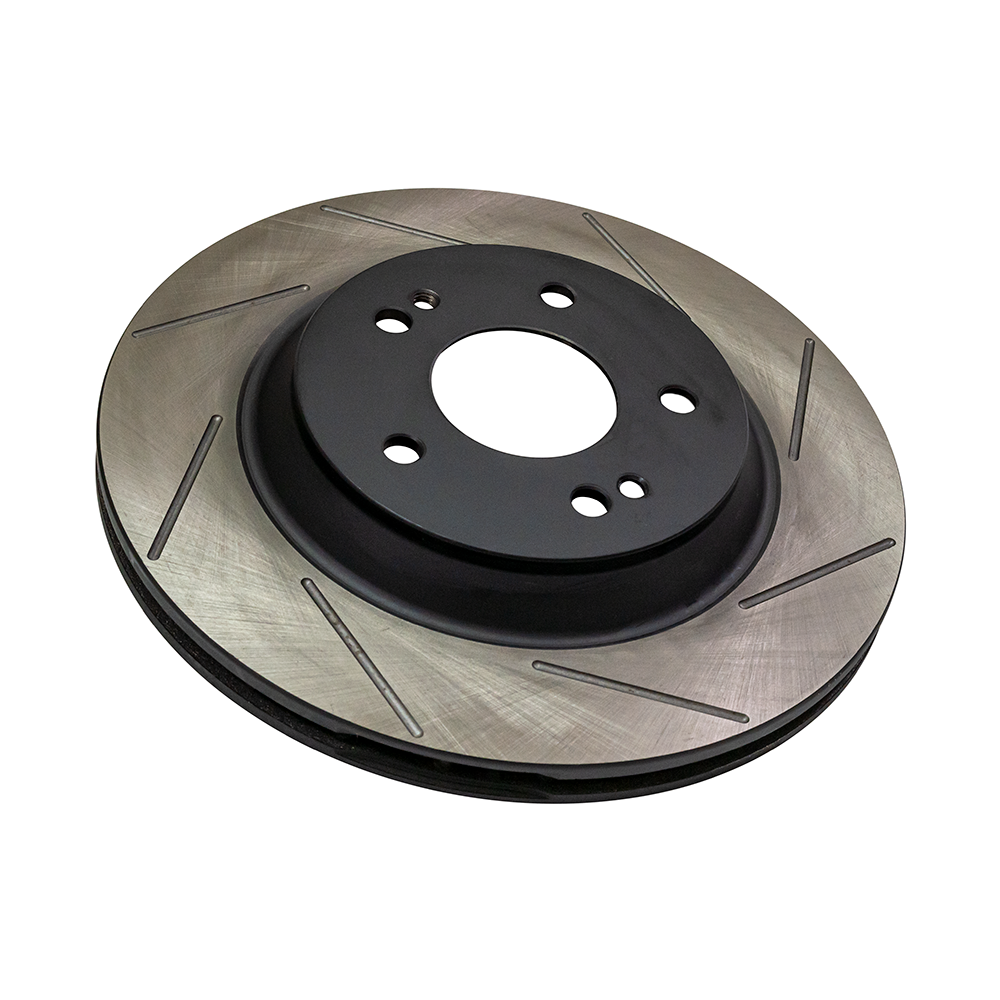

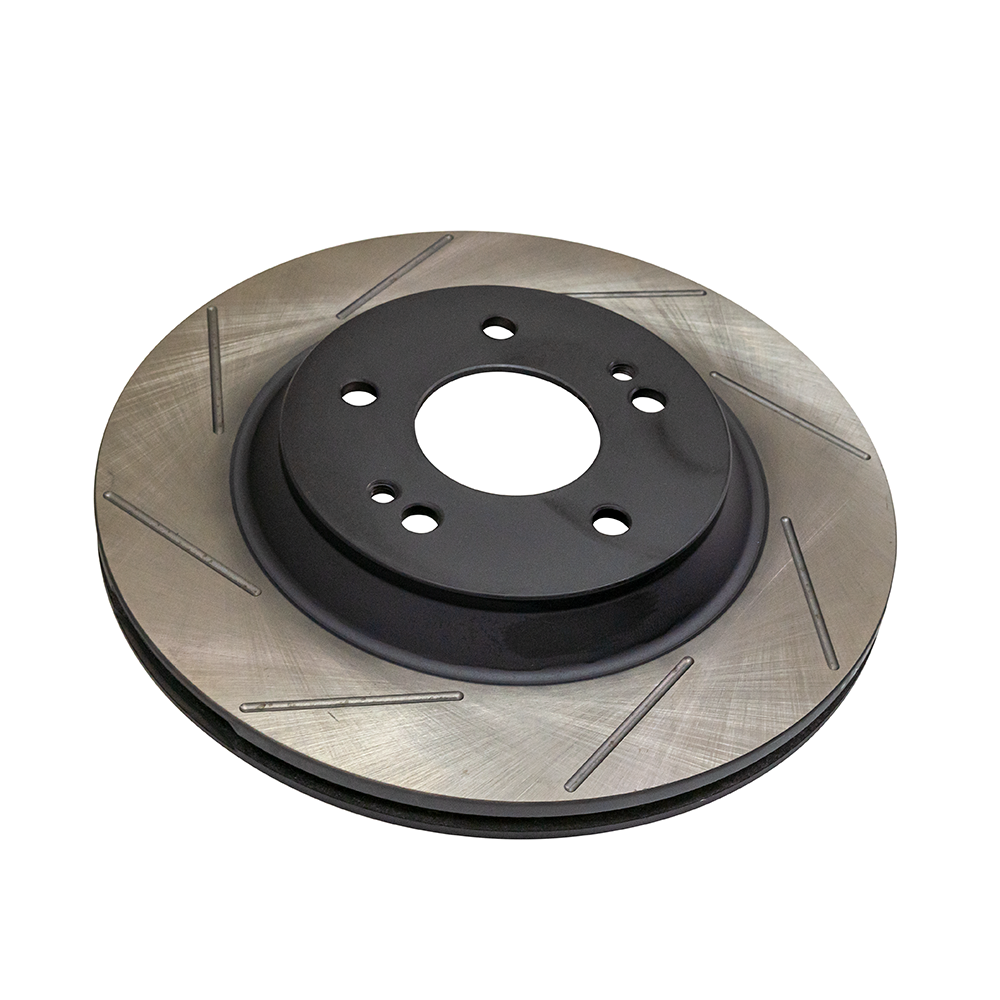

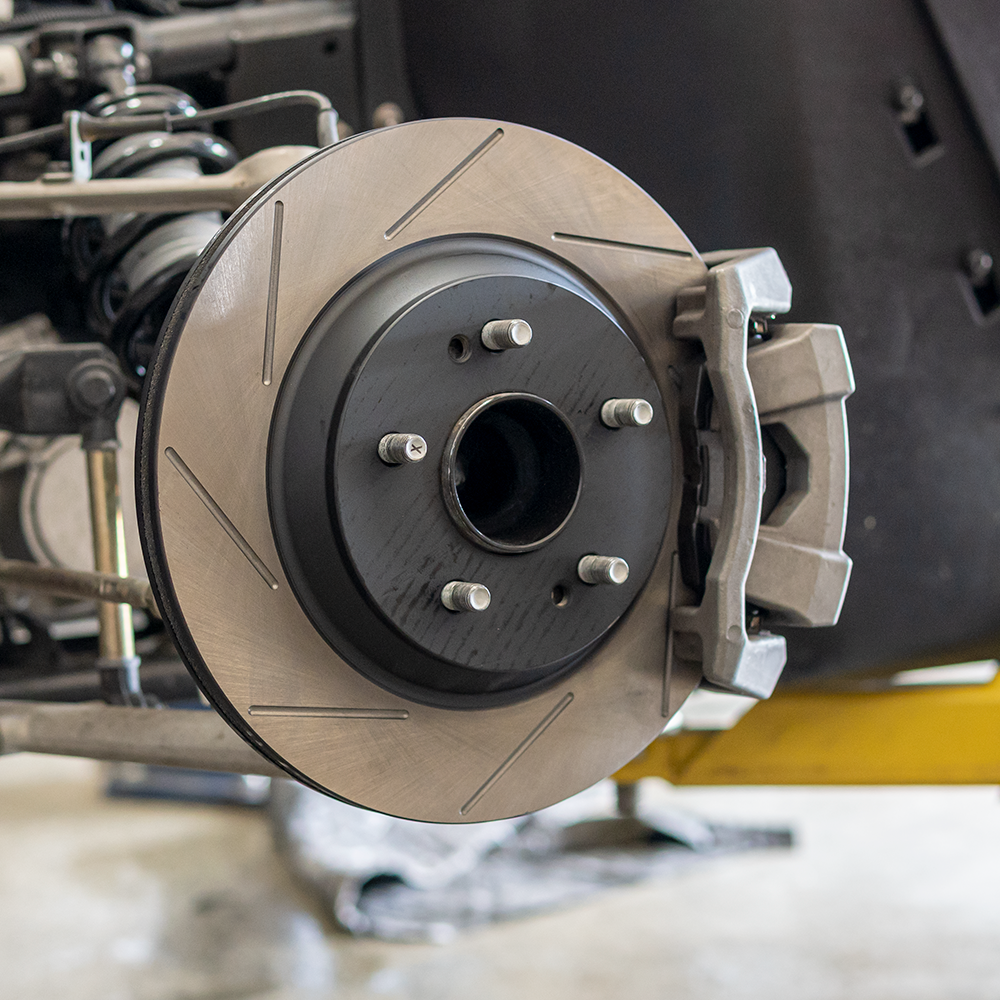

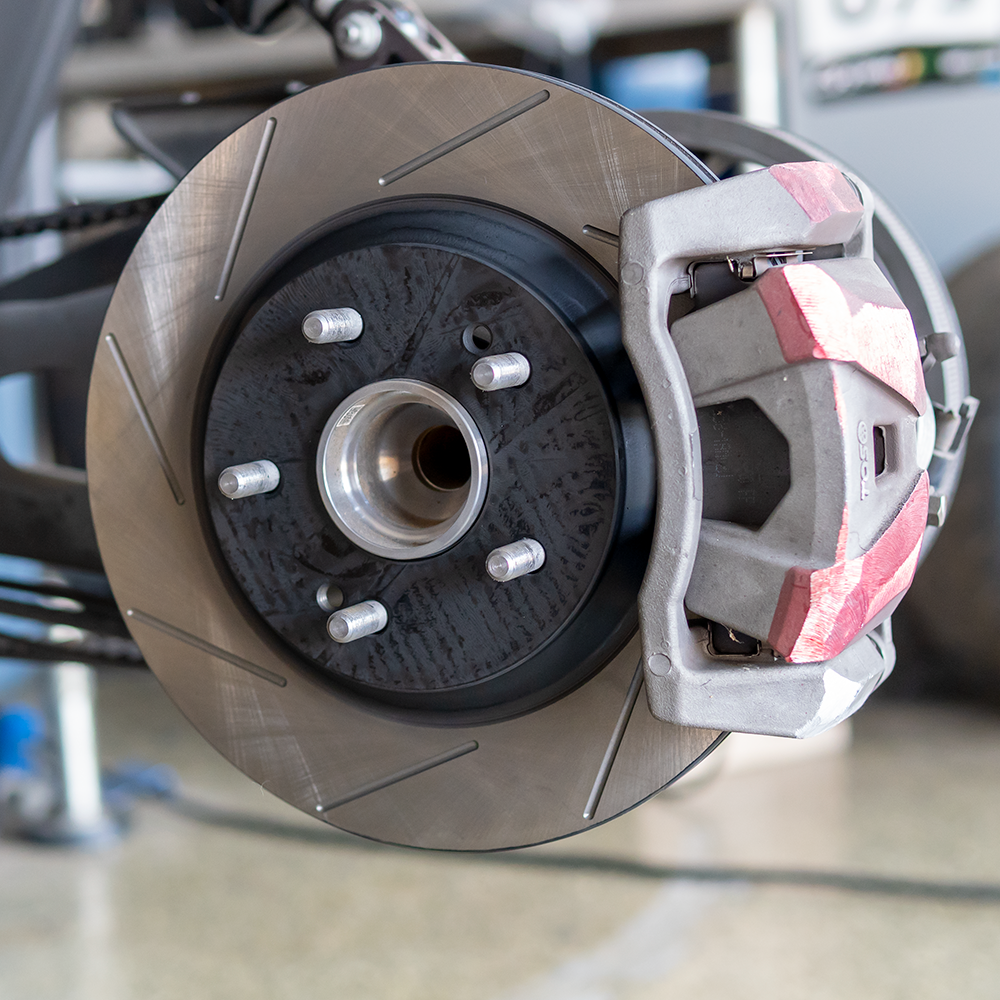

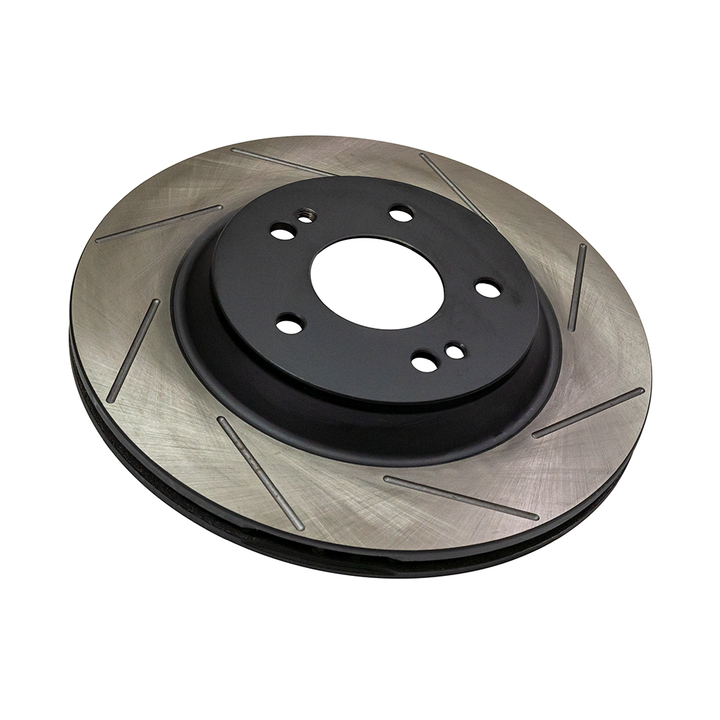

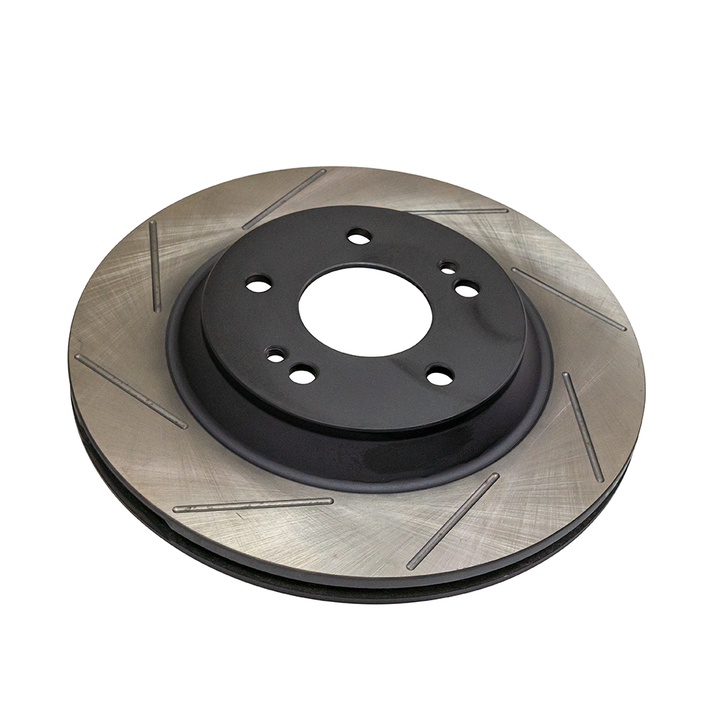

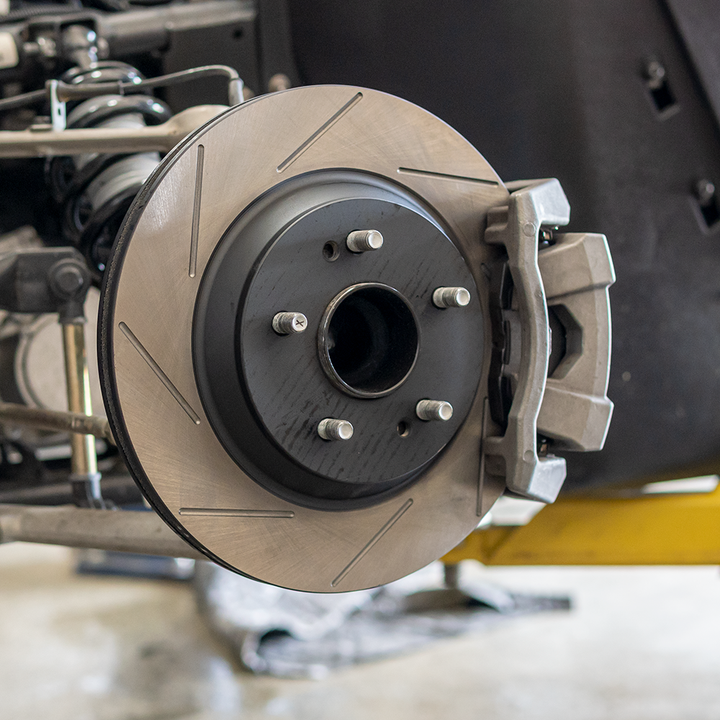

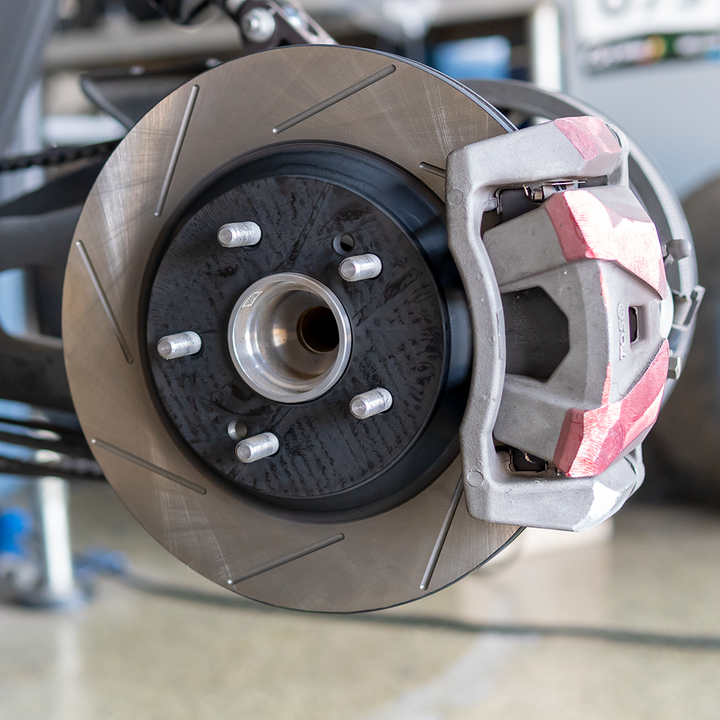

The public asked for it and ZZperformance listened. Introducing our ZZPerformance High Performance Slotted Rotors for the Polaris Slingshot. Our cast rotor blanks are blanchard ground to assure precise flatness and then machined with slots. A slotted rotor offers multiple distinct benefits under heavy braking: Brake fade, from high-temperature brake pad outgassing, can be significantly reduced, allowing gases and dust that is trapped between the pad and rotor to escape through the slots. The slots also shave off thin layers of brake pad material, reducing glazing and improving braking consistency. Slotted rotors also will not crack like drilled rotors can. Rotors are offered in sets of 3 on their own or if you would like to also greatly increase stopping power as well we also offer them in a discounted package with either Ferro Carbon or Ceramic pads made by Hawk.

Rotors and pads are all sold in complete sets to do all 3 wheels on the Slingshot.

Fits all models 2015-Current Year

Street Fero-Carbon

HPS 5.0

For years, engine builders have been pushing motors to the limits of their ability, and at Hawk Performance, we're closer than ever to pushing the ABS Rev Limiter to its limits. High Performance Street 5.0 pads give your vehicle the greatest stopping power and pedal feel without compromising ABS. HPS 5.0 is a Ferro-Carbon compound that provides advanced braking characteristics to enhance the driving experience. This compound combines the safety and quality of aerospace design with the braking technology of motorsports. The results are shorter stopping distances, improved performance under heavy braking conditions, and street car friendly characteristics.

· Aggressive torque

· Great rotor & pad wear life

· Smooth & predictable control

· Designed to deliver high deceleration rates

· Consistent brake release characteristics for a smooth braking feel

· All Hawk Performance compounds are not compatible with carbon ceramic rotors. Hawk pads are designed to work with Iron/Metal rotors.

· 100-750 F operating temperatures

· 100-550 F optimal temperature range

Street Ceramic

PERFORMANCE CERAMIC

Hawk understands the needs of today's ceramic brake pad users and has specifically formulated our composite material to meet - and beat - the stringent low noise, ultra-low dust performance standards they have set. Engineered to reduce brake NVH (Noise, Vibration and Harshness), Performance Ceramic is a premium disc brake pad that delivers excellent performance mile after mile. Providing a linear friction profile that allows your vehicle's ABS system to operate most effectively, our unique compound has the advantage of never sacrificing power to achieve traditional ceramic pad attributes. With Hawk's PC, you can expect reduced brake pad wear, longer rotor life, and our quietest ride ever.

· Extremely quiet

· Ultra-low dust

· Improved stopping power

· Gentle on rotors for extended pad life

· Stable friction output

· All Hawk Performance compounds are not compatible with carbon ceramic rotors. Hawk pads are designed to work with Iron/Metal rotors.

· 100-650 F operating temperatures

· 100-450 F optimal temperature range

Recommended Break-In Procedures for Cast Iron Brake Rotors

Our Steel / Iron rotors should be bedded in before being used on the street or under racing conditions. Proper bedding preps the rotor surface and makes them more resistant to thermal cracking under sever braking conditions. Your stock Slingshot pads will work great for this. The goal of this process is to slowly bring the rotors up to temperature. This reduces the chance of thermal shock which happens by uneven heating of the rotor surface.

1. Make sure the rotor surfaces are free from grease, oil, and brake fluid

2. Bring your Slingshot up to about 35mph and make several medium deceleration stops to slowly heat up the rotor. You want to keep the vehicle moving so do not come to a complete stop

3. Repeat this process but this time increase your speed to 55mph and again use medium deceleration

4. Now that the rotors are hot, let your Slingshot sit so the rotors can cool down to ambient air temp. This generally takes about an hour

5. With the rotors now bedded, you can now swap out your brake pads to the upgraded pads and repeat the process.