A hot engine heats up the air that is flowing through your intake. The engine is aluminum, as is the intake and they conduct heat very well. Your 180 deg engine adds unwanted heat to the LIM which houses the intercooler. That is why you need to upgrade with our ZZP LSJ phenolic spacer. A cooler charge will make more power. Keep in mind that removing heat adds power not only by increasing air density, but also by helping cool your IAT2s down to help prevent detonation.

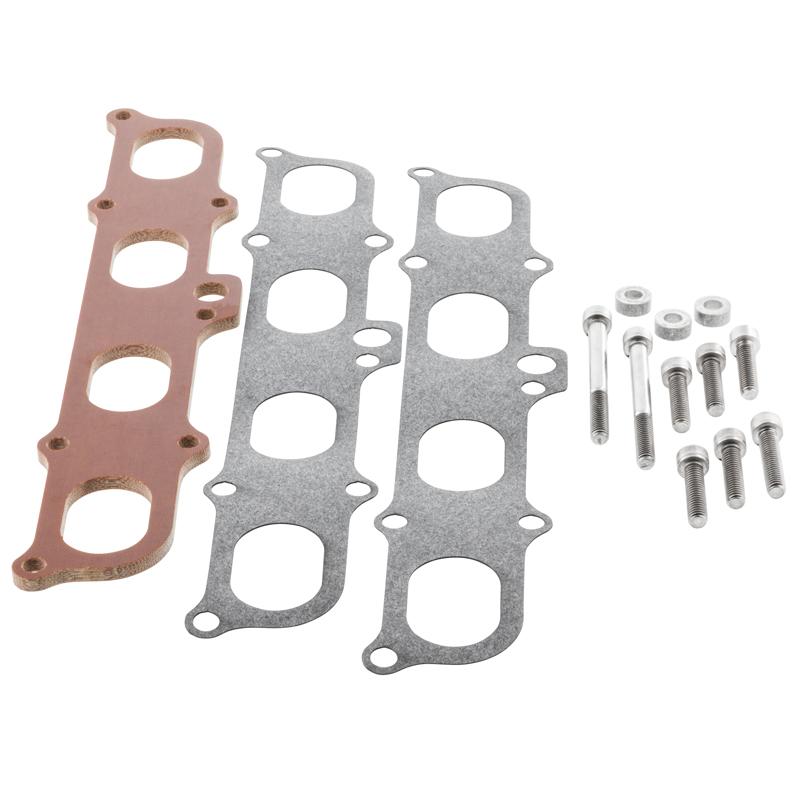

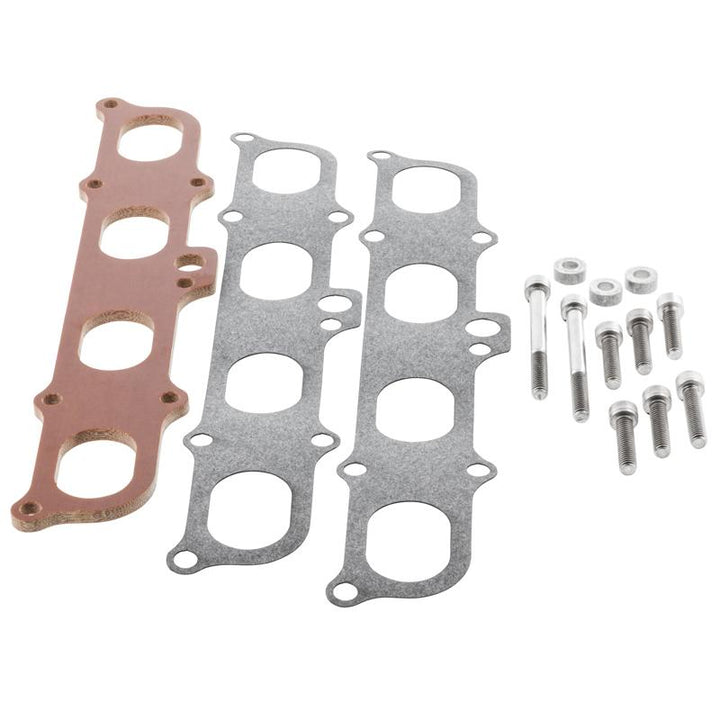

We isolate the intake from 95+% of its contact to the engine which is what is heating it up. See pic below showing that the heat from the engine is isolated where the intake connects to the engine.

The engine runs at approx 185 deg and has a direct metal to metal contact with a large surface area on the intake. This is constantly trying to heat the intake/IC system/blower to this temp. This puts additional heat into the IC system and is the reason on summer days you will see IATs at idle/cruise 40 to 60 deg over ambient. While the lower part of the intake has a mounting point, it is very small and bolts to a bracket which then bolts to the engine. This is quite a bit of separation and the contact is small enough to be negligible.

The air under the hood on a summer day is normally around 140 deg but air doesn't do a very good job at heating things, not like metal/metal or fluid/metal. So with the spacer you can expect a much cooler intake, much cooler blower and lower IATs all the time, even under boost. This gives more HP and much more consistent performance by eliminating heat soak and keeping the blower casing to rotor tollerance as small as possible.

Click to see customer post on Cobalt SS forum with a writeup and install instructions.

All this technology is borrowed from our pioneering work on the 3800's. There used phenolic to shield the blower IC from engine heat with fantastic results.

http://www.youtube.com/watch?v=qDlwo...layer_embedded

Recently viewed